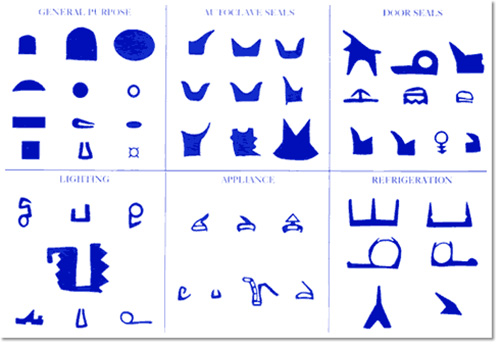

Silicone extrusions are available in various profiles to suit your individual requirements. We are able to manufacture most profiles from samples or drawings.

Our extruded Sections are used in:

- Clean Room Doors

- Telecom Shelters

- Air Tight door seal application

- Bakery Ovens

- Freeze Doors

- Pharmaceuticals Processing Machine's Door

- Autoclaves, Isolators & Dry Heat Sterilizers etc...

On request We will be happy to send you drawings of our standard profiles from which you will be able to select the profile which suits your application effortlessly.

Based on your application of the products we have different Rubber types available, It is necessary to select Proper rubber type and hardness for the required product ,so as to obtain the

best performance from the product.

| Grade | Shore hardness | Temperature range | General description |

| General purpose (GP) | 40-80 | -60 to +200°C | Good all round physical properties. Available in many shore hardnesses. FDA approved |

| Non-postcured (NPC) | 60 | -60 to +250°C | Low compression set & improved temperature resistance ,usually used where product is subjected to pressure and shape retention is important factors. |

| High Tear(HT)(Peroxide cure) | 40-80 | -60 to +200°C | Good tensile and wear strength& transparency.Uses include peristaltic pumps. FDA approved. |

| High Tear transparent (HTHT)(platinum cure) | 40-70 | Up to +200°C | Very pure silicone content with no by-products remaining. Mainly used in medical applications. |

| F-viton | 40-70 | -60 to +280° | Excellent high temp resistance. Retains properties over long periods when expose to harsh temps. |

| Flame Retardant electrically conductive | 60-70 | Up to +200°C | Combining the properties of both flame retardant and electrically conductive grades. |

Coil Length (mtrs): 10 (minimum order quantity)

Colours: White , Red , Transparent or translucent (as standard ). Any color available on request